Find more details in this pdf: SoftPLC Specifications.

All SoftPLCs are programmed and configured with TOPDOC NexGen software.

|

|

512-264-8390 or |

|

PACs, PLCs,

RTUs, HMI/SCADA, Protocol Gateways,

PLC/HMI

Upgrades and more… |

|

|

SoftPLCs can be used for applications small to large - simple machine control, RTUs, line controls, through plant-wide DCS systems. |

|

All SoftPLC controllers have the same rich core set of features and functions. |

|

Functions common to all

SoftPLC models:

|

|

Find more details in this pdf: SoftPLC Specifications. All SoftPLCs are programmed and configured with TOPDOC NexGen software. |

|

|

|

The Smart SoftPLC is a

flexible and powerful

controller:

|

|

|

|

A SoftPLC NeoPAC is physically small, yet functionally huge.

NeoPAC is perfect for a

wide range of applications!

A NeoPAC includes:

|

|

|

|

The MLX family of SoftPLCs address low I/O count applications. The MLX SoftPLCs combine a CPU with an I/O block.

The MLX SoftPLC is a

great alternative to A-B MicroLogix. It

is similar in size and I/O mix, plus you

can re-use existing logic, HMI’s and

other networked devices.

|

|

|

|

The Hardbook SoftPLC is a family of open architecture controller CPUs that can connect to a wide variety of I/O and communication networks. Each model has unique hardware characteristics, but all include:

|

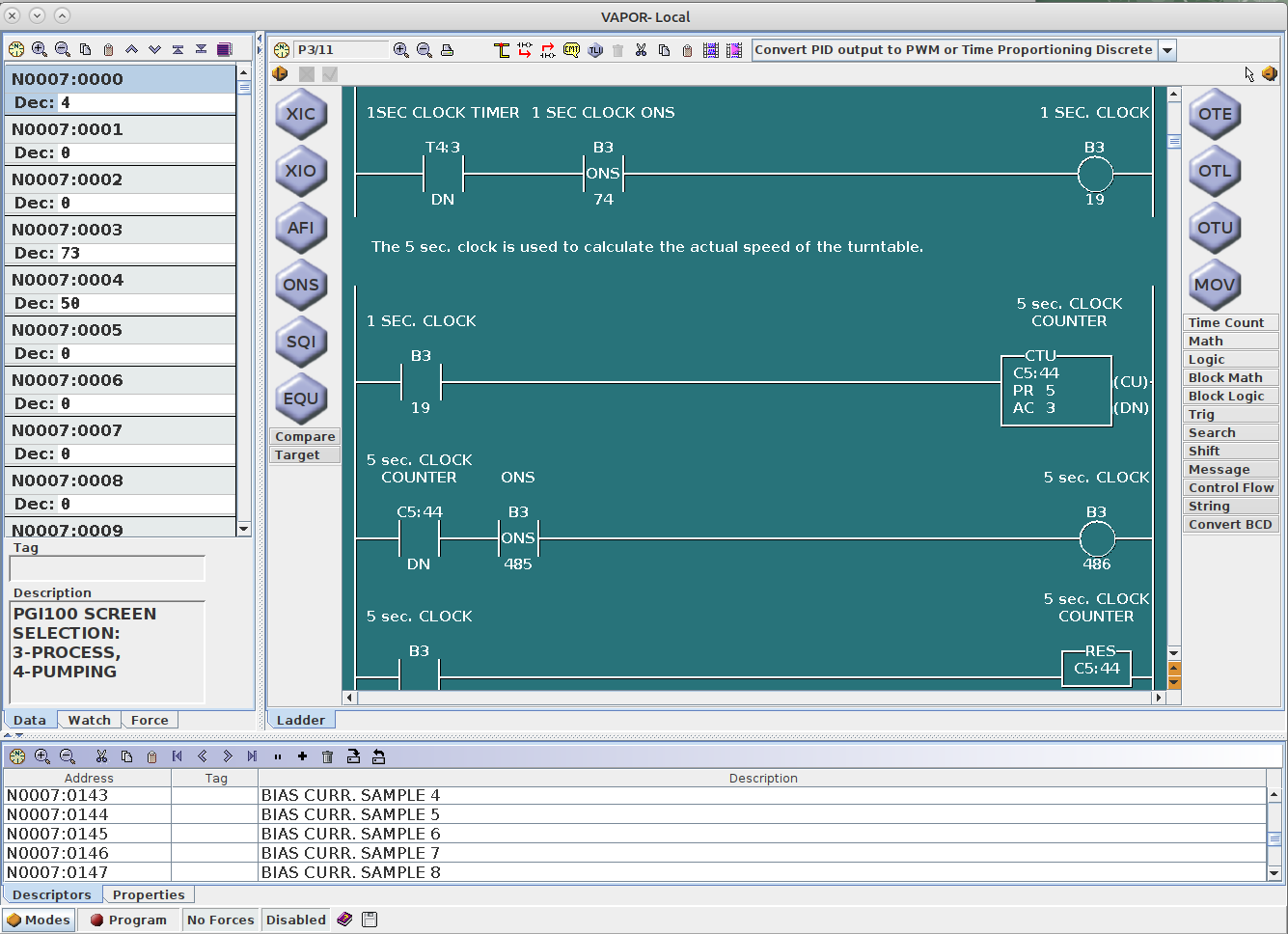

TOPDOC NexGen Editor for SoftPLC

|

|

TOPDOC® NexGen is the programming and configuration software for all SoftPLCs. Its sleek user interface means both infrequent and "power" users can easily access the features and functions they need. |

|

Smart Backplane3 CPU with

Tealware Modules

|

Tealware™ is a high density modular I/O system, suitable for applications requiring as few as 16 digital and/or 4 analog points up through thousands of I/O points.

|

|

Tealware can also be used as Ethernet I/O

with any SoftPLC CPU or

3rd party system that can drive ModbusTCP

I/O.

|

|

|

SoftPLC Corp. offers and supports these

I/O products, in addition to Tealware: |

|

|

The MLX series is a compact block of Ethernet I/O with a mix of digital/analog points. |

|

|

The A-Series includes modules with many digital/analog signal options for use on Ethernet or serial networks. |

|

|

Plus, with SoftPLC’s included

drivers and communication ports, you

can use I/O products from many vendors

with any SoftPLC

CPU.

|

|

More migration solutions for A-B based

systems: RIO/DH+ Gateways!

|

|

|

Continuing to use obsolete PLC systems is risky, and not only due to abysmal spare parts availability. Time and money can be lost due to PLC limits and other factors such as programming software not being compatible with new PC’s.

We provide fantastic, limited downtime,

inexpensive upgrade

paths for A-B PLC’s - superior to those

from Rockwell Automation!

|

A-B PLC-2, PLC-3, PLC-5 programming

software is still available from SoftPLC

Corp.

|

|

|

Allen-Bradley (Rockwell Automation) has obsoleted their programming software for the PLC-2, PLC-3, and PLC-5, hoping to "motivate" you to purchase new hardware, even for systems that are still meeting your needs. |

|

|

Since 1984 we continue to provide software for A-B PLC’s, called TOPDOC®, and it runs on modern PC’s! |

|

Also see our excellent upgrade options from older A-B PLC’s to a state-of-the-art SoftPLC CPU, using your existing A-B I/O and networks. |

|

|

|

The SoftPLC-500 Remote I/O Adapter

provides support of SLC-500 I/O racks on

A-B RIO (blue-hose) or Ethernet:

|

Upgrade HMI’s on A-B DH+/RIO using

SoftPLC Gateways

|

|

|

|

SoftPLC RIO/DH+ Gateways help you replace equipment in phases (eg: drives, HMI’s, scales, robots) in outdated Allen-Bradley PLC-based control systems - eliminating the need to obtain funding or scheduling a lengthy downtime for a complete rip/replace project. |

|

|

Our migration solutions are suitable whether you want to continue to use Rockwell Automation products, move to another vendor’s products, or a combination. |

|

|

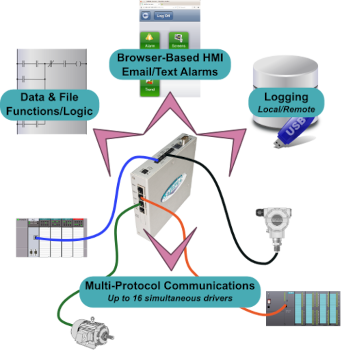

SoftPLC Gateways are the most flexible and powerful protocol converters on the market, also providing comprehensive industrial data management: |

SoftPLC Gateways do more

|

|

SoftPLC’s TagWell provides IIoT

remote system management solutions

|

|

TagWell™ provides solutions for IIoT (Industrial Internet of Things) - it is a powerful, configurable platform for comprehensive, scalable remote system management. |

|

TagWell uses Internet cloud technologies and low-cost M2M cellular communications. Combined with our SoftPLC controllers and Gateways, TagWell makes it easy to monitor, control, acquire data from, and troubleshoot remote systems. |

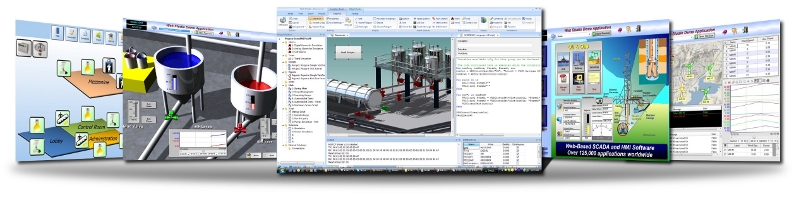

SoftPLC Web Studio SCADA array of screens

|

|

SoftPLC Web Studio is supervisory control and data acquisition software (SCADA) that includes the building blocks for even the largest systems, yet is priced to be practical for even smaller operator interface (HMI) applications. It features graphical operator interface, alarms, trends, logic, recipes, reports, database interface, and more. |

|

The same development software can be used to create applications for any of our HMI’s or to run on your own Windows computers, from mobile devices up through redundant Windows Server systems. |

SoftPLC Web Studio HMI

|

|

|

|

|

|

|

|

SoftPLC products are used by thousands of companies in a wide variety of industries and applications throughout the world. Here are a few examples: |

|

SoftPLC Corporation’s products are proven solutions for a diverse set of industries and applications: |

|

|

SoftPLC’s approach to open architecture control has been proven in harsh conditions and challenging applications including those requiring speed, extensive communications, and 24/7/365 reliability. |

|

SoftPLC Corporation’s many thousands of customers include End Users, OEM’s and System Integrators throughout the world. |

|||

|

Small, medium, and large companies benefit from our innovative technology, reliable products, and legendary service. |

|||

|

|||

|

SoftPLC Corporation’s products are used worldwide in a wide range of industries and applications. |

||||||||||||

|

|

|

|

(end of SoftPLC/TOPDOC list) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click below for a full product download. It includes software, user manual/tutorial, and demo application. This unlicensed download is an evaluation version providing 40 hours of development. Demo applications can run for 1 hour each session. |

|

|

|

Technical Support Support for licensed software products is available by phone/email during our normal hours. TOPDOC and SoftPLC products include 1 year of Support and Maintenance from date of initial shipment. Support Extensions can be purchased after the warranty period expires. |

|

Updates & Upgrades The first digit in the software release number is the Version. The number(s) after the decimal point are the Revision. Revision Updates can be downloaded by customers whose software is at the current Version, and are eligible for Support. Version Upgrades can be purchased or may be available for customers with Premium Support. |

|

For unlock passwords and compatibility information, contact support. |

|

We provide flexible training options to best meet customer needs. Training sessions can range from multi-day hands-on sessions to a few hours of web-based discussion. |

|

Training can include multiple products, or be designed to address specific customer needs such as (a) specific software/hardware used, (b) student experience levels or (c) other factors. |

|

Contact sales to discuss options, costs, and scheduling. |

|

All hardware products include a warranty period of 1 year or longer. During the warranty period, defective products are repaired/exchanged at no charge. |

|

Out-of-warranty products can often be repaired or traded-up to more modern equivalents. See Terms & Conditions of Sale for details. |

|

Contact support for Return Authorizations and to discuss your problem. |

|

Revision |

updates are for customers at the current Version and in Support. |

||||||||||||

|

Version |

upgrades require Premium Support and/or purchase. |

||||||||||||

|

For unlock passwords, update procedures or compatibility info, Contact support.

|

|||||||||||||

| Product | Final Version |

|---|---|

|

TOPDOC SoftPLC (TDZ) |

4.5 |

|

TOPDOC PLC-5 |

4.4 |

|

TOPDOC PLC-3 |

4.0 |

|

TOPDOC PLC-2 |

5.28 |

|

SoftPLC Corporation is an industrial automation products provider. We manufacture PAC/PLC systems, protocol converters, HMI/SCADA and related equipment. |

|

|

Our extensive experience in developing open architecture, productivity enhancing products leads to our reputation of being among the most innovative and highest quality software developers in the industrial sector. Many "industry firsts" have been incorporated into our products over the past 40 years. |

|

|

SoftPLC Corporation, founded in 1983, is a privately held, woman owned Texas corporation based near Austin, Texas. |

|

|

Mission Statement

We shall continuously strive to exceed customer expectations by providing innovative technology, reliable products, and legendary service. |

|

|

Phone: |

512-264-8390 or |

|

Sales: |

|

|

Support: |

|

|

E-Commerce: |

|

|

Address: |

SoftPLC Corporation |

|

Regular Hours: |

M-F 6am - 6pm (Central Time) |

|

LinkedIn Page: |

|

|

YouTube Channel: |

|

Purchase directly from SoftPLC Corp. or through an authorized reseller. |

|

|

Purchase Direct: |

|

|

If you also need application/installation assistance, consider an authorized SoftPLC integrator. |

|

|

Do you sell automation

products?

We have Reseller opportunities available. |

|

|

Our System Integrator program is a key part of our business strategy. |

|

|

End Users - Benefit

with qualified local engineering,

installation and support for systems using

SoftPLC Corporation products. |

|

|

Are you an Automation Integrator?

|

|